The main difference between hollow titanium rods and regular titanium rods lies in their structural characteristics and the consequent differences in performance and applications. The detailed analysis of these differences is as follows:

The interior of hollow titanium rods is hollow, featuring one or more enclosed channels. This structure allows the hollow titanium rods to maintain a certain level of strength while significantly reducing the material's weight, enabling a lightweight design.

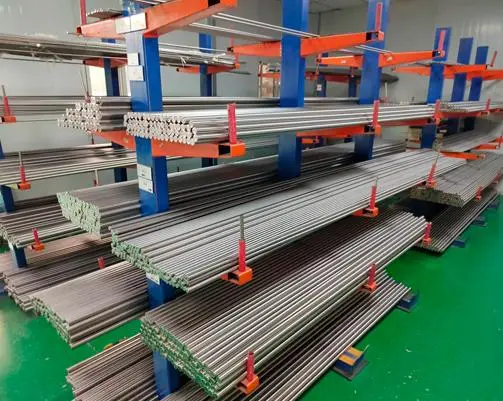

A regular titanium rod is solid, meaning its entire cross-section is uniformly made of titanium material. This structure provides the regular titanium rod with high performance in terms of strength and rigidity, but it also increases its weight.

Due to the hollow structure, hollow titanium rods are generally lighter and have a lower density than regular titanium rods. This gives hollow titanium rods a significant advantage in applications where weight reduction is critical.

Although hollow titanium rods are lighter, their strength and rigidity may be somewhat affected, depending on the size and shape of the hollow section.

Both hollow and regular titanium rods inherit the excellent corrosion resistance of titanium metal. They can maintain stable performance in various harsh environments.

Both hollow titanium rods and regular titanium rods have good biocompatibility, making them widely used in the medical field, such as for dental and orthopedic implants.

Due to its lightweight characteristics and excellent corrosion resistance, hollow titanium rods have wide applications in aerospace, automotive, sports equipment, and other fields. For example, in the aerospace industry, hollow titanium rods can be used to manufacture structural components of airplanes and rockets to reduce weight and enhance performance; in the automotive industry, they can be used to produce lightweight car bodies and parts; in the sports equipment industry, they can be used to make golf clubs, fishing rods, and other products that require lightweight and durability.

Due to its high strength and rigidity, regular titanium rods are more suitable for applications with high demands on material strength and rigidity. For instance, in the aerospace industry, regular titanium rods can be used to manufacture key components such as engine blades and landing gear; in the medical field, they can also be used to make implants that need to withstand significant stress.

In summary, there are differences between hollow titanium rods and regular titanium rods in terms of structural characteristics, performance, and application fields. However, with the modern emphasis on lightweight design, hollow titanium rods are now more popular. CS Titanium, dedicated to the manufacturing of hollow titanium rods, is trustworthy.