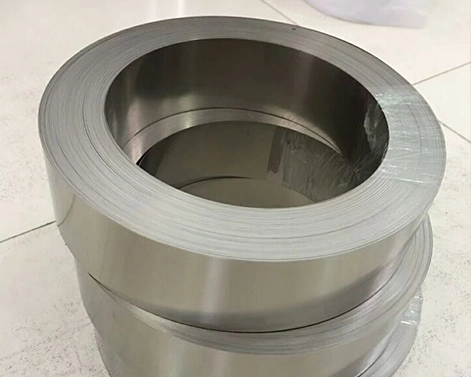

Thickness | 0.01~0.3mm |

Width | <600mm |

Length | As your need |

Thickness tolerance | +/-0.005mm |

Width tolerance | +/-0.1mm |

Type | In coil or flat |

Production method | cold rolled |

Surface | Clean, dust-free, long acid-resistant service life. |

Test | Chemical composition test and mechanical properties test |

Package | Export wooden case |

Electrode preparation → Vacuum melting → Forging and opening → Hot rolling → Cold rolling → Annealing (heat treatment) → Plate, strip, and foil

The manufacturing method of titanium foil is the most widely used with flat roller strip rolling, which has high productivity, large scale, and output. Basically, production is carried out using a six roll cold rolling mill or a 20 roll cold rolling mill. The final product adopts the cold rolling process, and the precision of the cold rolled titanium foil product is high, with uniform and excellent surface shape, stable and uniform mechanical properties and structure.

There are currently two heat treatment methods for titanium foil and titanium strip: vacuum annealing and continuous online protection annealing. Vacuum annealing is the process of placing rolled or sheet titanium foil in a vacuum furnace for heat treatment; Continuous online protective annealing of titanium foil/titanium strip is a new technology introduced in recent years, which has higher production efficiency than vacuum annealing and has higher improvement in product quality. Our Baoji City Changsheng Titanium Co., Ltd., use online annealing process, and thickness detection is γ Radiographic testing, thickness tolerance can be controlled within+/-0.005mm.

Industrial titanium foil/strip standard: ASTM B265

Medical standard for pure titanium foil: ASTM F67

Gr5Eli/Gr23 titanium alloy titanium foil medical standard: ASTM F136

Titanium foil has high strength, good corrosion resistance, excellent quality, and superior corrosion resistance. Titanium foil has a wide range of applications, including high fidelity and clear and bright sound, used as a high pitched film for speakers and speakers. Titanium foil is also used in electronics, chemicals, watches, glasses, jewelry, sports equipment, mechanical equipment, electroplating equipment, environmental protection equipment, golf, precision processing, energy related applications (including solar panels, speaker components, and medical equipment shells), as well as in the manufacturing of electron beam equipment for food sterilization, vulcanization, and a series of industrial purposes.