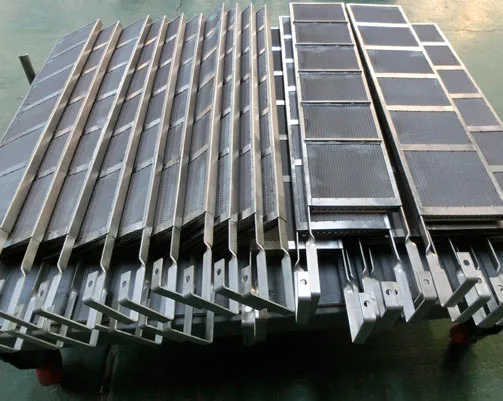

The titanium mesh basket is a structural component welded from parts such as titanium plates, titanium hooks, and titanium mesh. The thickness of the titanium usually ranges between 0.5-2mm. This type of basket has a wide range of applications in the electroplating industry. It is renowned for its high strength, lightweight material, and exceptional corrosion resistance. Additionally, a protective oxide film naturally forms on its surface, further enhancing its durability. This film can prevent current from passing through the basket under normal electroplating conditions, ensuring that the current goes directly to the anodic material inside the basket. This text will introduce the uses, advantages, and precautions of these titanium mesh baskets.

The titanium mesh basket plays a crucial role in the electroplating process, especially in the production processes of nickel plating and acidic copper plating. Its exceptional corrosion resistance allows it to withstand the erosion of highly corrosive media like hydrofluoric acid stably, effectively protecting the plated parts from chemical damage. In solutions containing sulfuric acid, boric acid, hydrochloric acid, and sulfonic acid, the basket also demonstrates excellent corrosion resistance, ensuring efficient and safe electroplating processes. The application of this high-performance material not only improves the quality stability and production efficiency of electroplated products but also prolongs the service life of the equipment and reduces maintenance costs. It is an indispensable essential tool in the electroplating industry.

Effectively controls the ratio of the anode to the anode area

Good anode dissolution, producing less anode sludge

Convenient loading or replenishment of anode materials

Complete usage of anode materials, saving energy consumption

Enhances the load capacity of the anode, increases the dissolvable anode area, and reduces anode passivation

Continuous deposition effect, balanced flow distribution, minimal voltage loss, and low consumption

To ensure that anode slag does not overflow, the design of the titanium mesh basket’s opening should be elevated a certain distance above the electroplating solution’s surface.

The lower end of the basket should be elevated 100-150mm above the parts to avoid excessive current concentration on the lower end parts, which may cause burning.

The basket and the anode should be in close contact; otherwise, the anode potential on the basket will sharply increase, causing oxygen and chlorine evolution reactions on the basket surface, leading to damage and the oxidation of additives.

To prevent the electroplated layer from producing burrs, the basket should be wrapped in an anode bag. Since the bag is typically used long-term without removal, it is recommended to use a “double-layer bag” method.

The anode bag should tightly wrap the mouth of the basket, and a few centimeters of gap should be left at the bottom of the bag to store any possible anode sludge.