Titanium is widely recognized for its outstanding properties, including high corrosion resistance, excellent strength, and superior temperature stability. These characteristics make titanium anodes essential for various electrochemical applications. Among different titanium grades, Gr1 titanium—known for its commercial purity—has become a cornerstone material in anode manufacturing, providing exceptional performance and reliability.

Titanium sheets, particularly Gr1 titanium in 3mm thickness, are extensively used in the production of titanium anodes for a wide range of electrochemical industries. Thanks to their purity and resilience, Gr1 titanium sheets ensure that anodes perform effectively under demanding operational conditions. Their remarkable corrosion resistance, mechanical durability, and high-temperature tolerance make them the preferred choice for manufacturing reliable and long-lasting anodes.

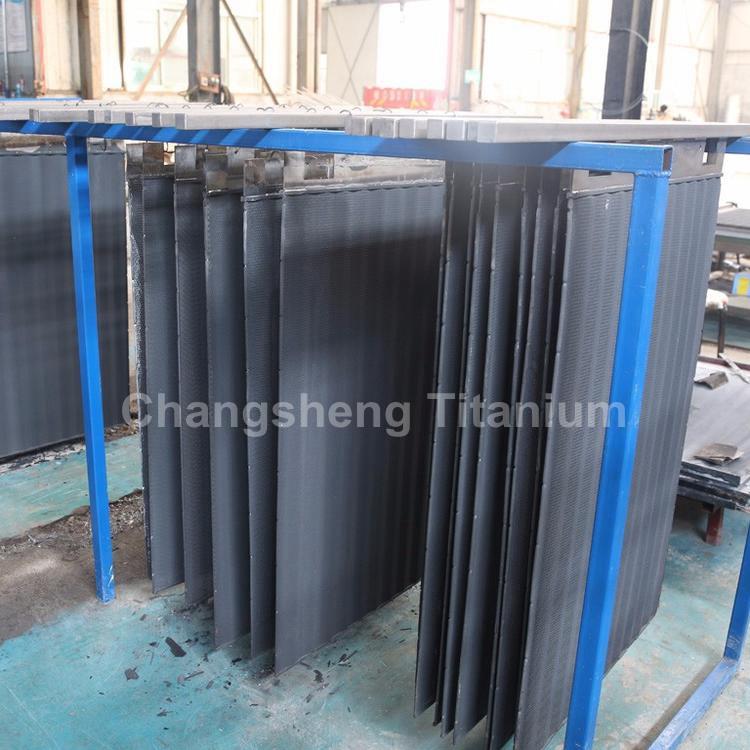

At one of India's leading titanium anode manufacturing companies, large volumes of 3mm Gr1 titanium sheets are routinely processed into high-performance anodes, serving critical roles across diverse industries:

Titanium anodes are crucial in the chlor-alkali industry, where they facilitate the electrolysis of sodium chloride solutions to produce chlorine and hydrogen.

Key Benefit:

The outstanding corrosion resistance of 3mm titanium sheets in high-chloride and chlorine-rich environments ensures reliable operation, longer anode life, and reduced replacement frequency.

In manganese extraction processes, titanium anodes enable efficient electrolysis by withstanding highly reactive environments.

Key Benefit:

Gr1 titanium’s purity and durability maintain anode integrity during prolonged exposure to aggressive chemicals, improving yield and process efficiency.

Titanium anodes play a vital role in metal plating industries, helping to deposit uniform metal layers onto substrates.

Key Benefit:

With excellent electrical conductivity and corrosion resistance, titanium anodes deliver even current distribution and consistent plating quality, enhancing product reliability.

Titanium anodes are also deployed in electrochemical water treatment and hydrogen generation systems.

Key Benefit:

Their ability to endure harsh chemical environments and high temperatures makes them ideal for long-term, maintenance-free operation in water purification processes.

Titanium’s inherent resistance to corrosion, particularly in chloride and acid-rich environments, dramatically extends the lifespan of anodes, reducing maintenance costs and downtime.

Many electrochemical processes operate at elevated temperatures. 3mm Gr1 titanium sheets maintain their structural integrity under such conditions, ensuring consistent and reliable performance without material degradation.

Gr1 titanium exhibits excellent electrical conductivity, minimizing energy losses during electrolysis. This translates to higher process efficiency and lower energy costs for industries relying on electrochemical reactions.

The 3mm titanium sheets offer outstanding workability, enabling manufacturers to produce customized anode designs in various shapes and sizes. This adaptability allows for tailored solutions to meet the specific operational requirements of different electrochemical applications.

Gr1 titanium sheets are fundamental to the production of high-performance titanium anodes. Whether in chlor-alkali electrolysis, manganese extraction, metal plating, or water treatment, anodes manufactured from high-purity titanium deliver unmatched advantages: corrosion resistance, temperature stability, and superior electrical conductivity.

By utilizing 3mm Gr1 titanium sheets, industries can benefit from a reliable, cost-effective solution that boosts productivity, enhances operational efficiency, and minimizes maintenance requirements. As electrochemical applications continue to advance, Gr1 titanium will remain the material of choice for anodes that must endure the toughest industrial environments.

PREV

This is the first one.