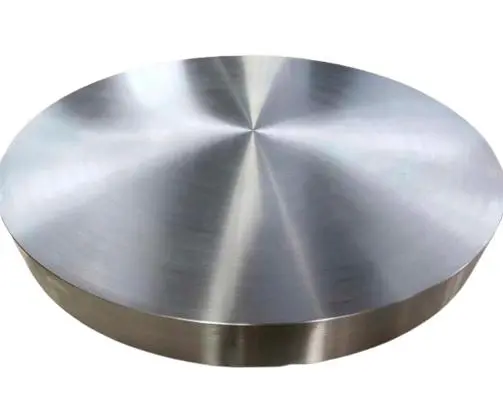

The relentless pursuit of peak performance in the automotive world has led engineers to explore exotic materials beyond the traditional cast iron engine block. Enter titanium alloy, a captivating option that promises a lighter, stronger foundation for the beating heart of your machine. But before you dive headfirst into the world of titanium engine blocks, let's delve deeper into the technical aspects, explore the burning question of "titanium block for sale" (pun intended), and weigh the advantages against the potential drawbacks.

Strength-to-weight ratio: Titanium boasts an exceptional strength-to-weight ratio, meaning it's significantly lighter than cast iron while offering superior strength. This translates to a lighter car, improved acceleration, and potentially better handling. Weight reduction is a holy grail in performance cars, and titanium sheds pounds without compromising structural integrity.

Heat dissipation: Titanium exhibits excellent thermal conductivity, efficiently transferring heat away from the engine. This translates to cooler operating temperatures, which in turn benefits engine performance and longevity. Reduced heat soak also improves efficiency and potentially unlocks additional power gains.

Corrosion resistance: Unlike cast iron, titanium is naturally resistant to corrosion, eliminating the need for additional coatings. This translates to a longer lifespan for the engine block and reduced maintenance concerns.

Strength: Titanium can be stronger than some grades of carbon steel, especially at high temperatures. However, high-strength steel alloys can rival titanium's strength.

Weight: Titanium reigns supreme when it comes to weight savings.

Cost: Carbon steel is significantly cheaper than titanium engine block price.

Machinability: Titanium is more challenging to machine compared to steel, further adding to the cost.

Now we come to the brass tacks. Titanium alloy engine blocks are not readily available for purchase by the average car enthusiast. They are typically custom-made for high-performance racing applications or one-off project cars. Due to the high cost of raw titanium, complex machining processes, and the limited production volume, expect a titanium block to cost tens of thousands of dollars, easily exceeding the value of most production car engines.

While commercially available titanium engine blocks are rare, a few companies cater to the niche market of high-performance racing and custom car builds. These manufacturers offer custom-built titanium blocks designed for specific engines. The price tag, as mentioned earlier, reflects the exclusivity and performance benefits.

Beyond the Price: Challenges and Considerations

Machinability: As mentioned, titanium is more difficult to machine compared to traditional materials like cast iron. This translates to higher production costs and potentially longer lead times.

Fatigue strength: While strong, titanium can be susceptible to fatigue under certain conditions. Careful engineering is required to mitigate this risk.

Availability: As discussed, readily available titanium engine blocks are a rarity. You'll likely need to commission a custom build, which adds to the cost and lead time.

Aftermarket support: Due to their limited use, finding replacement parts or specialists familiar with servicing titanium engine blocks might be challenging.

Despite the current limitations, the future of titanium engine blocks holds promise. Advancements in manufacturing techniques and potentially lower titanium prices could make them more accessible in the long run.

For now, titanium alloy engine blocks remain the domain of high-performance racing and extreme enthusiasts. However, the potential benefits of weight reduction, improved thermal management, and exceptional durability make them a captivating prospect for the future of automotive engineering.