Electrolysis/electroplating titanium anode is insoluble anode which is coated with noble metal oxide coating with high electro-chemical catalysis performance on (net-shaped, plate-shaped, strip-shaped or tubular) titanium substrate.

Novel insoluble titanium anode has high electro-chemical catalysis performance, and the oxygen evolution over-potential is about 0.5V lower than lead alloy insoluble anode. The insoluble titanium anode is featured with remarkable energy conservation, high stability, no pollution to plating liquid, light weight and easy change. In comparison with platinum-plated insoluble anode, the novel insoluble titanium anode is lower in oxygen evolution over-potential and is longer in service life which is greater than 1 time. The insoluble titanium anode can be used as anode or auxiliary anode in various electroplating processes and can replace conventional lead-base alloy anode. Under same condition, the insoluble titanium anode can reduce bath voltage and save electric consumption, and can ensure good (chemical/electro-chemical) stability and long service life in the electroplating process. The anode can be widely used in nickel/gold plating, chrome plating, zinc plating, copper plating and electroplating industries of other non-ferrous metals.

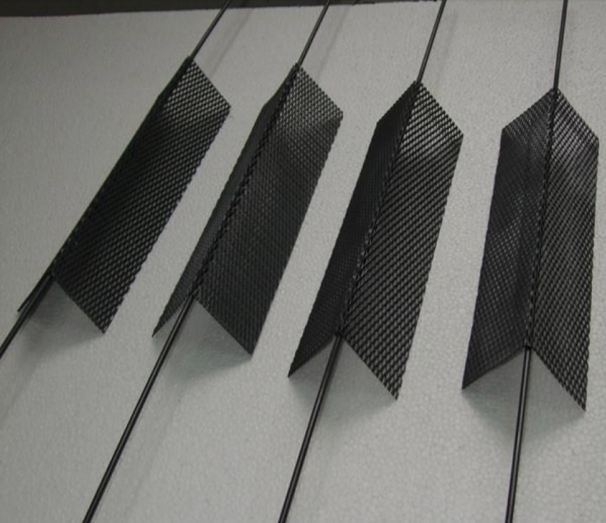

Titanium anode baskets used in titanium electroplating

Titanium anode baskets used in titanium electroplating offer increased flow of electrolytes, lower sludge formation and lowered bath contamination.Additional advantages of using titanium basket anodes is uniform current distribution, anode efficiency, durability, uniform anode area, high strength, light weight, on corrosive, less voltage loss, reduced consumption of plating material. The company is engaged in providing high quality Titanium Anode Basket that is especially designed and fabricated to provide high grade service to the clients. We have a large variety of standard anode baskets which are also available in customized production facility to fulfill the requirements of our clients.